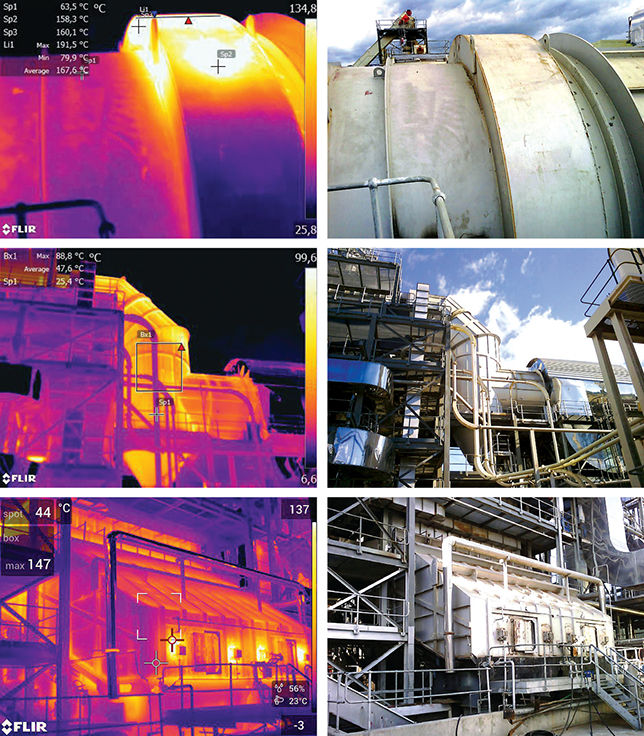

Our services include High-Temperature Endoscopy and Infrared Thermography, which enable us to detect potential safety hazards as well as optimize costs and prevent production losses.

Capable of operating within extremely harsh conditions our Endoscopy technology allows for real-time visualization of the furnace's interior, enabling us to assess the refractory's condition and schedule maintenance or rebuilds efficiently. The Infrared Thermography technology allows for constant monitoring of the metallic shell status such as damage to the shell lining and its remaining thickness along with the detection of hot spots.

In Incorporating our state-of-the-art technologies, we are able to provide innovative solutions that will enhance the service life of your operating assets. If you require our furnace inspection services, please contact us for more information. BENEFITS:

Compilation of comprehensive records of wear for the refractory lining.

Reduced unplanned stoppages.

Maximizing furnace equipment availability, increasing yields, and reducing operating costs.

Efficient planning for scheduled shutdowns and refractory materials supplies.

Confident budget planning for the purchase of very expensive items such as refractories.

Knowledge sharing with plant maintenance staff.

ABOUT OUR COMPANY, HISTORY, AND PARTNERS

Dickinson Group of Companies (DGC) was founded in 1910. For comprehensive information about Our Company – History, Vision & Values, Strategy, Global Alliances, Africa Footprint, Our Commitment to Safety, Anti-Corruption Policy, References, and Industrial Solutions, please visit our websites.